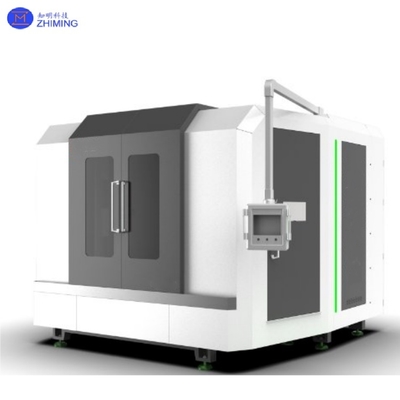

Diamond Wire Single-Line Cutting Machine for SiC/Sapphire/Quartz/Ceramic Material

The diamond wire single-line cutting machine is a high-precision processing equipment for hard and brittle materials, utilizing diamond-impregnated wire (diamond wire) as the cutting medium to achieve efficient and low-loss cutting through high-speed reciprocating motion. This machine is primarily designed for processing hard and brittle materials such as sapphire, silicon carbide (SiC), quartz, glass, silicon rods, jade, and ceramics, including operations like cropping, truncation, cutting-off, and slicing—especially suitable for precision cutting of high-hardness and large-sized materials.

Featuring a modular design, the machine can be equipped with optional rotary worktables, high-tension systems, and circular cutting functions to meet diverse processing needs. Compared to traditional abrasive wire cutting or laser cutting, diamond wire cutting offers higher efficiency, lower material loss, and superior surface quality, making it widely applicable in industries such as semiconductors, photovoltaics, LEDs, precision optics, and jewelry processing.

Technical Specification of Diamond Wire Single-Line Cutting Machine

|

Item

|

Parameter

|

Item

|

Parameter

|

|

Maximum work size

|

600×500(mm)

|

Constant tension(N)

|

15.0N~130.0N

|

|

Swing angle

|

0~±12.5

|

Tension accuracy(N)

|

±0.5

|

|

Swing frequency

|

6~30

|

Running direction

|

Bidirectional or unidirectional

|

|

Lift stroke(mm)

|

650(mm)

|

Sliding stroke(mm)

|

Maximum 500 (mm)

|

|

Lift speed(mm/min)

|

0~9.99

|

Storage(L)

|

30

|

|

rapid travelling speed(mm/min)

|

200

|

Power consumption

|

44.4kw

|

|

Center Distance of Cutting Guide Wheel(mm)

|

680~825

|

Mortar motor

|

0.2kw

|

|

Diamond wire diameter(mm)

|

φ0.12~φ0.45

|

Noise

|

≤75dB(A)

|

|

Running speed (m/s)

|

1500m/min

|

Cutting speed

|

<3 hours (6-inch SiC) (m/s²)

|

|

Acceleration (m/s²)

|

5

|

Power Line Specifications

|

4x16+1x10(mm²)

|

|

Size(length/width/height)

|

2680×1500×2150(mm)

|

Cutting accuracy

|

<3μm(6寸SiC)(N)

|

|

Weight

|

3600kg

|

Gas supply Requirements

|

>0.5MPa

|

Working Principle of Diamond Wire Single-Line Cutting Machine

The core working principles of the diamond wire single-line cutting machine include:

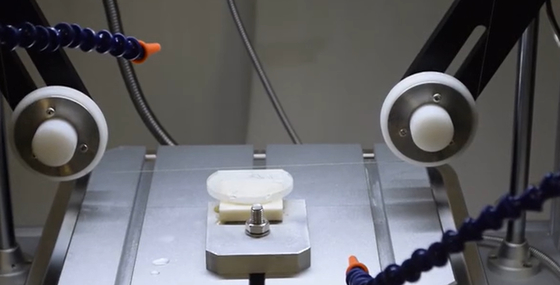

- High-Speed Diamond Wire Motion: The diamond-coated wire moves reciprocally at speeds up to 1500 m/min, driven by a guide wheel system, achieving material cutting through the grinding action of diamond particles.

- Precision Feeding System: The workpiece is fed via servo motor control combined with high-precision linear guides, ensuring dimensional accuracy up to ±0.02 mm.

- Cooling and Debris Removal: A water-based coolant flushes the cutting area to reduce thermal impact and remove debris, preventing edge chipping.

- Optional Functional Extensions:

- Rotary Worktable: Enables multi-angle cutting (e.g., circular or bevel cuts) for cylindrical or irregularly shaped workpieces.

- High-Tension System: Enhances cutting stability for ultra-hard materials (e.g., SiC ingots).

Key Features of Diamond Wire Single-Line Cutting Machine

1. High-Efficiency Processing

- Maximum wire speed of 1500 m/min, ideal for efficient cutting of ultra-hard materials like SiC and sapphire, with 50% higher efficiency than traditional abrasive wire cutting.

- Optimized wire bow control technology minimizes material waste, enabling slice thicknesses as low as 0.2 mm and improving material utilization by 30%.

2. Intelligent Operation and Flexibility

- Equipped with a user-friendly touchscreen interface for one-touch parameter storage and recall, streamlining operations.

- Rapid switching between cutting modes (e.g., straight-line, curved-line, multi-wafer synchronous cutting) to adapt to varied processing requirements.

3. Modular Functional Extensions

- Optional rotary worktable for precision circular or angled cuts on cylindrical workpieces (e.g., silicon rods, raw jade).

- High-tension system (20-60 N range) prevents wire breakage and deviation during hard material cutting.

- Supports automatic tool alignment and vision positioning for enhanced precision in complex-shape processing.

4. Robust Structural Design

- High-strength cast/forged machine body offers superior vibration resistance and long-term stability, ensuring consistent cutting accuracy.

- Critical components (e.g., guide wheels, spindles) feature ceramic or tungsten carbide coatings, extending service life beyond 5000 hours.

Application Fields of Diamond Wire Single-Line Cutting Machine

1. Semiconductor Industry

- SiC ingot slicing: For power device substrate preparation, with cutting loss below 100 μm.

- Sapphire window processing: Precision cutting for LED epitaxial wafers and optical windows.

2. Photovoltaic Industry

- Silicon rod truncation and slicing: For monocrystalline/polycrystalline solar cell production, with cutting speeds up to 800 m/min.

3. Precision Optics and Jewelry

- Quartz glass and jade cutting: Delivers high surface quality (Ra <0.5 μm), reducing post-polishing steps.

4. Research and Specialty Ceramics

- Aluminum nitride (AlN) and zirconia ceramic slicing: Meets demands for high-temperature components in aerospace.

Conclusion

With its high efficiency, precision, and low material loss, the diamond wire single-line cutting machine has become essential for hard and brittle material processing. As demand grows for third-generation semiconductors (SiC/GaN) and high-end optical components, its applications in 5G communications, electric vehicles, and photovoltaic energy will expand further. Future advancements will focus on AI-driven control and automated loading systems, steering the technology toward intelligent and unmanned operation.

Q&A of Diamond Wire Single-Line Cutting Machine

1. Q: What materials can be cut with a diamond wire saw?

A: Diamond wire saws excel at cutting hard brittle materials including silicon carbide (SiC), sapphire, quartz, ceramics, and semiconductor crystals with precision up to ±0.02mm.

2. Q: How does diamond wire cutting compare to laser cutting for SiC wafers?

A: Diamond wire cutting achieves 50% faster processing of SiC with <100μm material loss versus laser's thermal damage risk and higher kerf loss.

Tag: #Diamond Wire Single-Line Cutting Machine, #Customized, #SiC/Sapphire/Quartz/Ceramic Material Processing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!