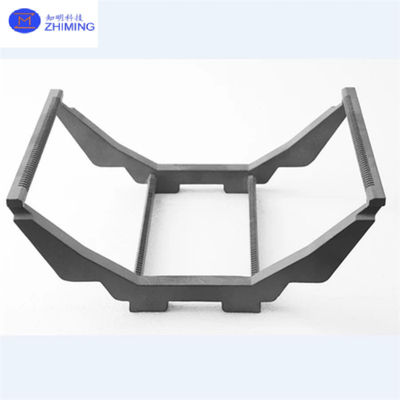

Customized SiC Ceramic Boat Carrier for Wafer Handling

The Customized Silicon Carbide (SiC) Ceramic Boat Carrier is a high-performance wafer handling solution designed for semiconductor, photovoltaic, and LED manufacturing processes. Engineered for high-temperature stability, chemical resistance, and ultra-low contamination, this carrier ensures safe and efficient wafer transport in demanding environments such as CVD, diffusion furnaces, and oxidation chambers.

Key Advantages of SiC Ceramic Boat

High Thermal Stability – Withstands temperatures up to 1,600°Cwithout deformation.

Chemical Inertness – Resists acids, alkalis, and plasma erosion, ensuring long-term durability.

Low Particle Generation – Minimizes contamination in EUV and advanced node fabrication.

Customizable Design – Tailored for wafer size, slot pitch, and handling requirements

Ideal for semiconductor fabs, MEMS production, and compound semiconductor processing

Specification

| Silicon Carbide Content | - | % | >99.5 |

| Average Grain Size | - | micron | 4-10 |

| Bulk Density | - | kg/dm^3 | >3.14 |

| Apparent Porosity | - | Vol % | <0.5 |

| Vickers Hardness | HV0.5 | Kg/mm^2 | 2800 |

| Modulus of Rupture (3 points) | 20°C | MPa | 450 |

| Compression Strength | 20°C | MPa | 3900 |

| Modulus of Elasticity | 20°C | GPa | 420 |

| Fracture Toughness | - | MPa/m^1/2 | 3.5 |

| Thermal Conductivity | 20°C | W(m*K) | 160 |

| Electrical Resistivity | 20°C | Ohm.cm | 10^6-10^8 |

| Coefficient of Thermal Expansion | a

(RT"800°C) | K^-1*10^-6 | 4.3 |

| Max. Application Temperature | Oxide Atmosphere | °C | 1600 |

| Max. Application Temperature | Inert Atmosphere | °C | 1950

|

Applications of SiC Ceramic Boat

1. Semiconductor Manufacturing

✔ Diffusion & Annealing Furnaces

- High-Temperature Stability – Withstands 1,600°C (oxidizing) / 1,950°C (inert) without deformation.

- Low Thermal Expansion (4.3×10⁻⁶/K) – Prevents wafer warpage in rapid thermal processing (RTP).

✔ CVD & Epitaxy (SiC/GaN Growth)

- Gas Corrosion Resistance – Inert to SiH₄, NH₃, HCl, and other aggressive precursors.

- Particle-Free Surface – Polished (Ra <0.2μm) for defect-free epitaxial deposition.

✔ Ion Implantation

- Radiation-Hardened – No degradation under high-energy ion bombardment.

2. Power Electronics (SiC/GaN Devices)

✔ SiC Wafer Processing

- CTE Matching (4.3×10⁻⁶/K) – Minimizes stress in 1,500°C+ epitaxial growth.

- High Thermal Conductivity (160 W/m·K) – Ensures uniform wafer heating.

✔ GaN-on-SiC Devices

- Non-Contaminating – No metal ion release vs. graphite boats.

3. Photovoltaic (Solar Cell) Production

✔ PERC & TOPCon Solar Cells

- POCl₃ Diffusion Resistance – Withstands phosphorus doping environments.

- Long Service Life – 5-10 years vs. 1-2 years for quartz boats.

✔ Thin-Film Solar (CIGS/CdTe)

- Corrosion Resistance – Stable in H₂Se, CdS deposition processes.

4. LED & Optoelectronics

✔ Mini/Micro-LED Epitaxy

- Precision Slot Design – Holds fragile 2"–6" wafers without edge chipping.

- Cleanroom-Compatible – Meets SEMI F57 particle standards.

5. Research & Specialty Applications

✔ High-Temp Material Synthesis

- Sintering Aids (e.g., B₄C, AlN) – Chemically inert in 2,000°C+ environments.

- Crystal Growth (e.g., Al₂O₃, ZnSe) – Non-reactive with molten materials.

FAQ

Q1: What wafer sizes are supported?

Standard: 150mm (6"), 200mm (8"), 300mm (12"). Customization available upon request.

Q2: What is the lead time for customized designs?

- Standard models: 4–6 weeks.

- Fully customized: 8–12 weeks (depending on complexity).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!