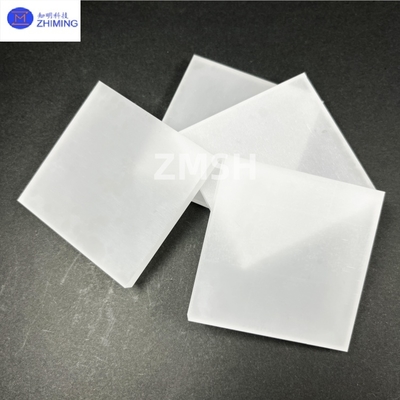

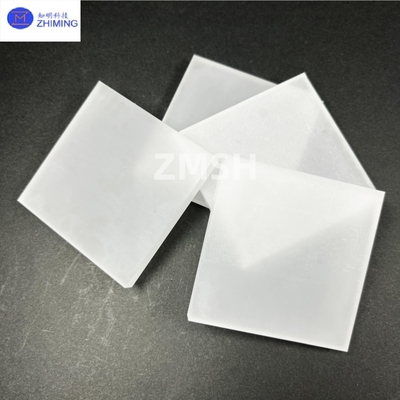

Sapphire Square Plate Single crystal Al₂O₃ Diameter 5.5 mm Thickness 6.04 mm

The Sapphire Square Plate is a precision optical component manufactured from high-purity single-crystal aluminum oxide (Al₂O₃) through directional cutting and double-sided polishing. With dimensions of 5.5mm (diameter) × 6.04mm (thickness), this custom-sized plate is engineered for applications demanding stringent dimensional tolerances and superior optical performance. Leveraging sapphire’s inherent physical advantages—including exceptional hardness and high-temperature resistance—this product is widely utilized in advanced optics, semiconductors, medical devices, and precision electronics.

Sapphire Square Plate Material Properties

1. Ultra-High Hardness

- Mohs hardness of 9 (second only to diamond), providing exceptional resistance to scratches and abrasion.

- Suitable for high-frequency precision friction scenarios, such as sensor protective windows and optical lens covers.

2. Broad-Spectrum Optical Transmission

- Transmits light across ultraviolet (200 nm) to mid-infrared (5.5 μm) wavelengths.

- Achieves >90% transmittance in the visible spectrum (400–800 nm), enabling high-precision optical devices like laser windows and infrared detectors.

3. Extreme Environmental Resistance

- High-Temperature Stability: Melting point of 2050°C and low thermal expansion coefficient (5.3×10⁻⁶/°C), ensuring stability from -200°C to 800°C.

- Chemical Inertness: Resists acids, alkalis, and oxidation, ideal for harsh environments (e.g., oil well sensors, chemical reactors).

4. Birefringence and Low Scattering

- Hexagonal crystal lattice induces birefringence (Δn = 0.008), requiring controlled crystallographic orientation (e.g., C-plane or R-plane cutting).

- Low scattering (haze <1%) ensures optical clarity in imaging systems.

5. High Thermal Conductivity and Electrical Insulation

- Thermal conductivity: 35–42 W/m·K (superior to glass), enabling efficient heat dissipation.

- Electrical resistivity: >10¹⁶ Ω·cm, preventing current leakage in high-power electronics.

Sapphire Square Plate Key Applications

1. Photoelectronic Devices

- LED Substrates: Sapphire Square Plate acts as a growth base for GaN-based LEDs, enhancing light extraction efficiency (>80%) for Mini LED backlights and automotive lighting.

- Laser Windows: Sapphire Square Plate used in fiber lasers and medical laser systems, enduring high-energy pulses.

2. Semiconductor Packaging and Sensors

- Power Device Protection: Sapphire Square Plate encapsulates IGBT and SiC MOSFETs, leveraging high thermal conductivity to reduce thermal resistance (e.g., in EV inverters).

- Optical Sensors: Fabricates infrared thermometers and gas sensor windows, utilizing broad-spectrum transmission for spectral analysis.

3. Aerospace and Defense

- Infrared Windows: Integrated into missile guidance systems and satellite infrared detectors, withstanding 1000°C+ surface temperatures during hypersonic flight.

- Bulletproof Transparent Armor: Replaces conventional glass, resisting ballistic impacts (V50 limit >600 m/s) while maintaining optical clarity.

4. Consumer Electronics and Medical

- Wearables: Sapphire Square Plate used in smartwatch displays and AR glasses, balancing wear resistance and transparency (6.04 mm thickness for slim designs).

- Medical Endoscopes: Biocompatible surface-treated windows for high-temperature autoclave sterilization (134°C/30 min).

5. Industrial and Research

- High-Temperature Probes: Sapphire Square Plate monitors boiler levels and oil well temperatures in corrosive environments (e.g., deep-sea exploration).

- Quantum Device Substrates: Sapphire Square Plate supports superconducting films (e.g., MgB₂) for quantum computing and superconducting circuits.

Recommended Sapphire Optical Windows

Sapphire Square Plate Q&A

Q1: What are the key advantages of sapphire square plates?

A1: Sapphire square plates offer ultra-high hardness (Mohs 9), broad-spectrum transparency (UV to mid-IR), and exceptional thermal stability (-200°C to 800°C), ideal for wear-resistant optics and extreme-environment electronics.

Q2: Where are sapphire square plates commonly used?

A2: They are widely applied in LED substrates (enhancing light extraction), laser windows (withstandinging high-energy pulses), and aerospace infrared detectors (resisting 1000°C+ temperatures).

Tags: #Sapphire Square Plate, #Single crystal Al₂O₃, #Diameter 5.5 mm, #Thickness 6.04 mm

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!